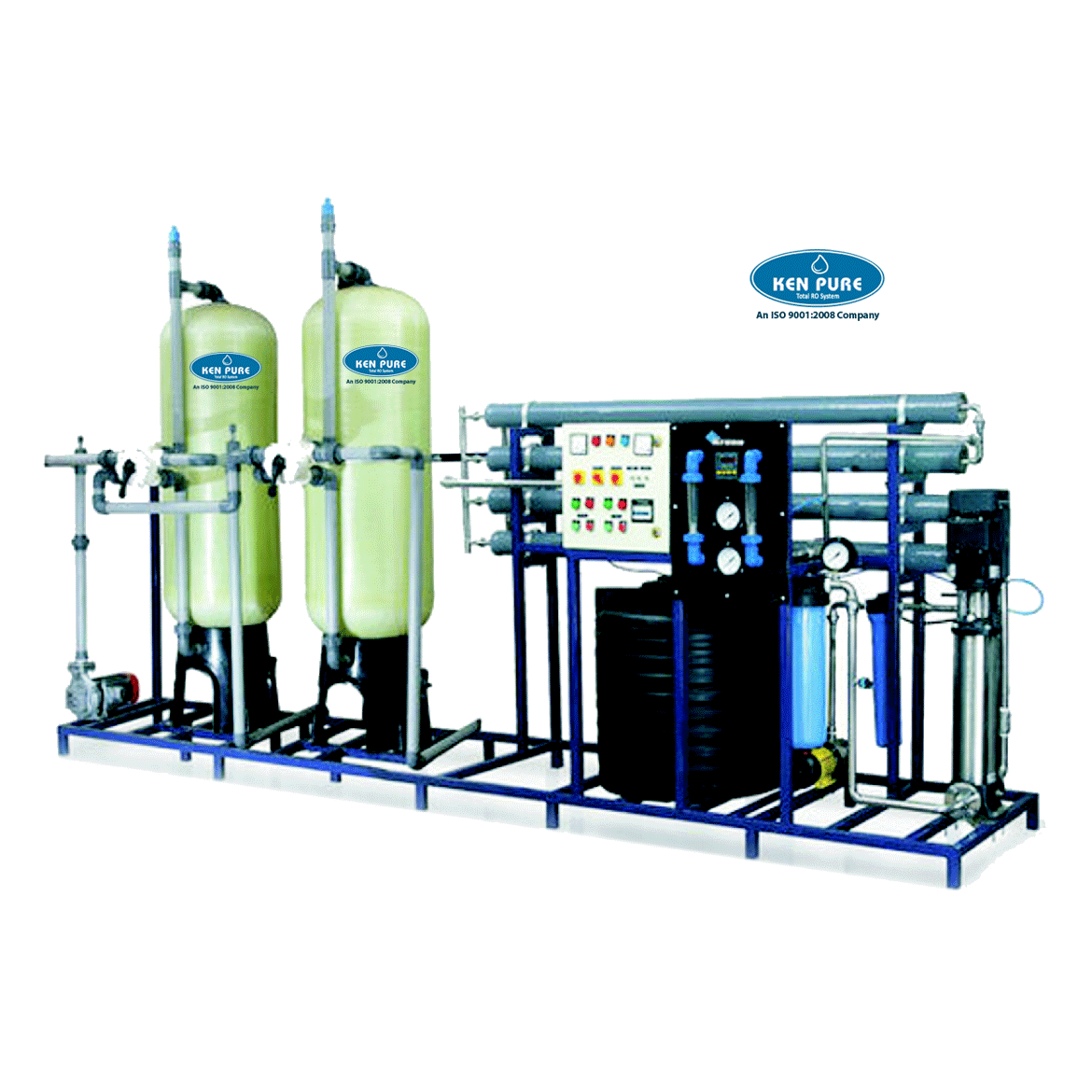

Kenpure’s KP1000-10000LPH commercial and industrial water purifier provides multi-stage water purification such as RO, UV and UF, which in turn purifies water without any dissolved impurities such as chemicals and minerals. KP1000-10000LPH also has TDS controller which keeps essential natural minerals in the water, and provides 100% pure, tasty and safe drinking water for your consumption.

- RO+UV+UF Purification: Multi-stage purification process of RO, UV and UF gives total protection from bacteria and viruses

- Fully Automatic: Fully automatic operation with auto-start and auto-off

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane. This membrane-technology is not properly a filtration method. In RO, an applied pressure is used to overcome osmotic pressure, a colligative property, that is driven by chemical potential, a thermodynamic parameter. RO can remove many types of molecules and ions from solutions and is used in both industrial processes and in producing potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective," this membrane should not allow large molecules or ions through the pores (holes), but should allow smaller components of the solution (such as the solvent) to pass freely.

UV radiation from ultraviolet water systems alone is not suitable for water with high levels of suspended solids, turbidity, color, or soluble organic matter. These materials can react with UV radiation, and reduce disinfection performance. Water turbidity makes it difficult for the ultraviolet radiation to penetrate water. If your water supply has these characteristics, a sediment prefilter (5 micron or less) should be installed before your UV water purification system to remove particulate matter prior to UV water disinfection.

Ultrafiltration (UF) is a variety of membrane filtration in which hydrostatic pressure forces a liquid against a semipermeable membrane. Suspended solids and solutes of high molecular weight are retained, while water and low molecular weight solutes pass through the membrane. This separation process is used in industry and research for purifying and concentrating macromolecular (103 - 106 Da) solutions, especially protein solutions. Ultrafiltration is not fundamentally different from microfiltration, nanofiltration or gas separation, except in terms of the size of the molecules it retains. Ultrafiltration is applied in cross-flow or dead-end mode and separation in ultrafiltration undergoes concentration polarization.

| Purification Capacity: |

1,000 to 10,000 liters/hour |

| Maximum Duty Cycle: |

40,000 to 400,000 liters/day |

| GAC Filter: |

20", 1 number |

| Micron PP: |

20", 1 number |

| Sediment CTZ: |

20", 1 number |

| Post Carbon: |

1 number |

| RO Membrane: |

4 numbers |

| Input TDS: |

upto 100 PPM |

English

English